The Ultradrum®

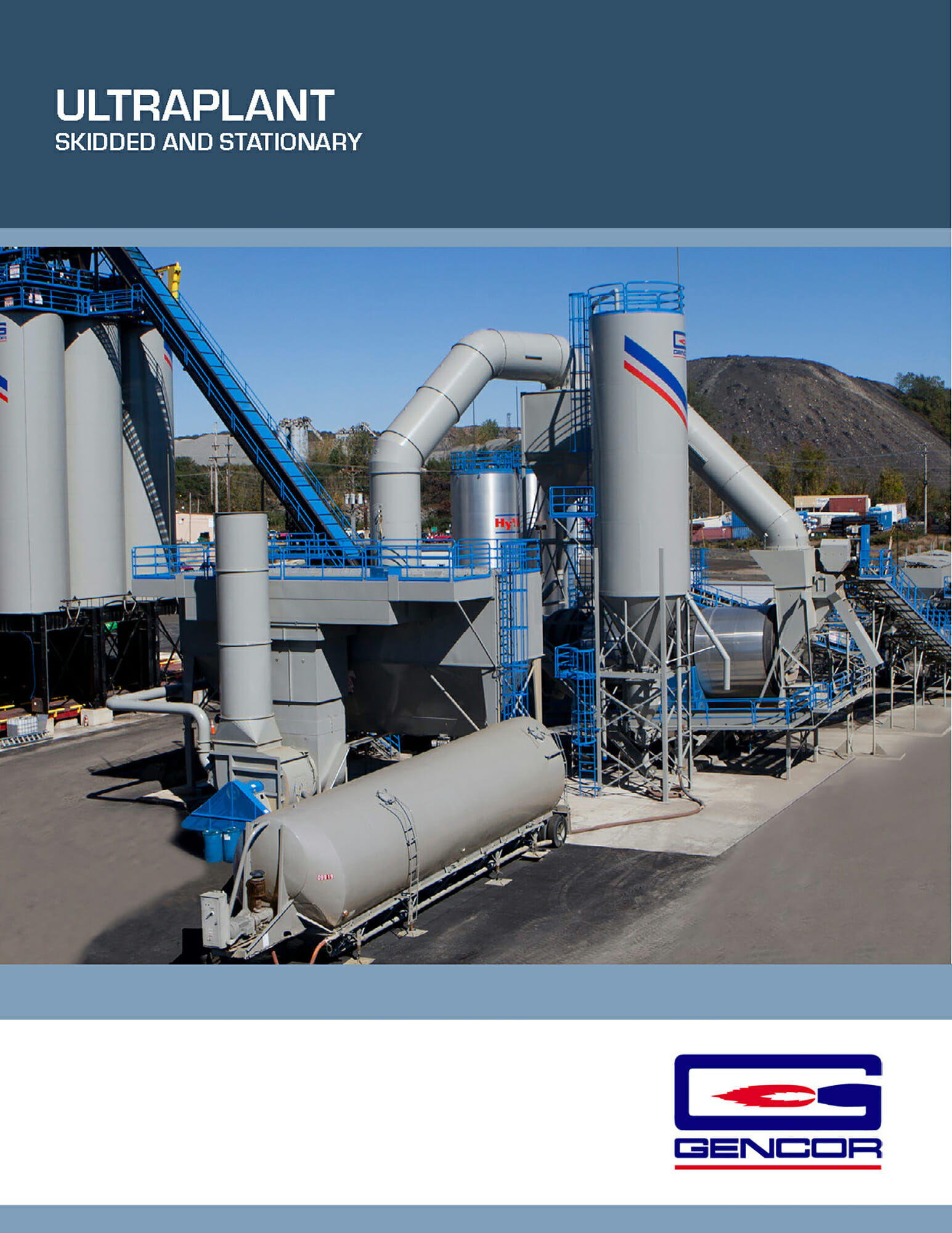

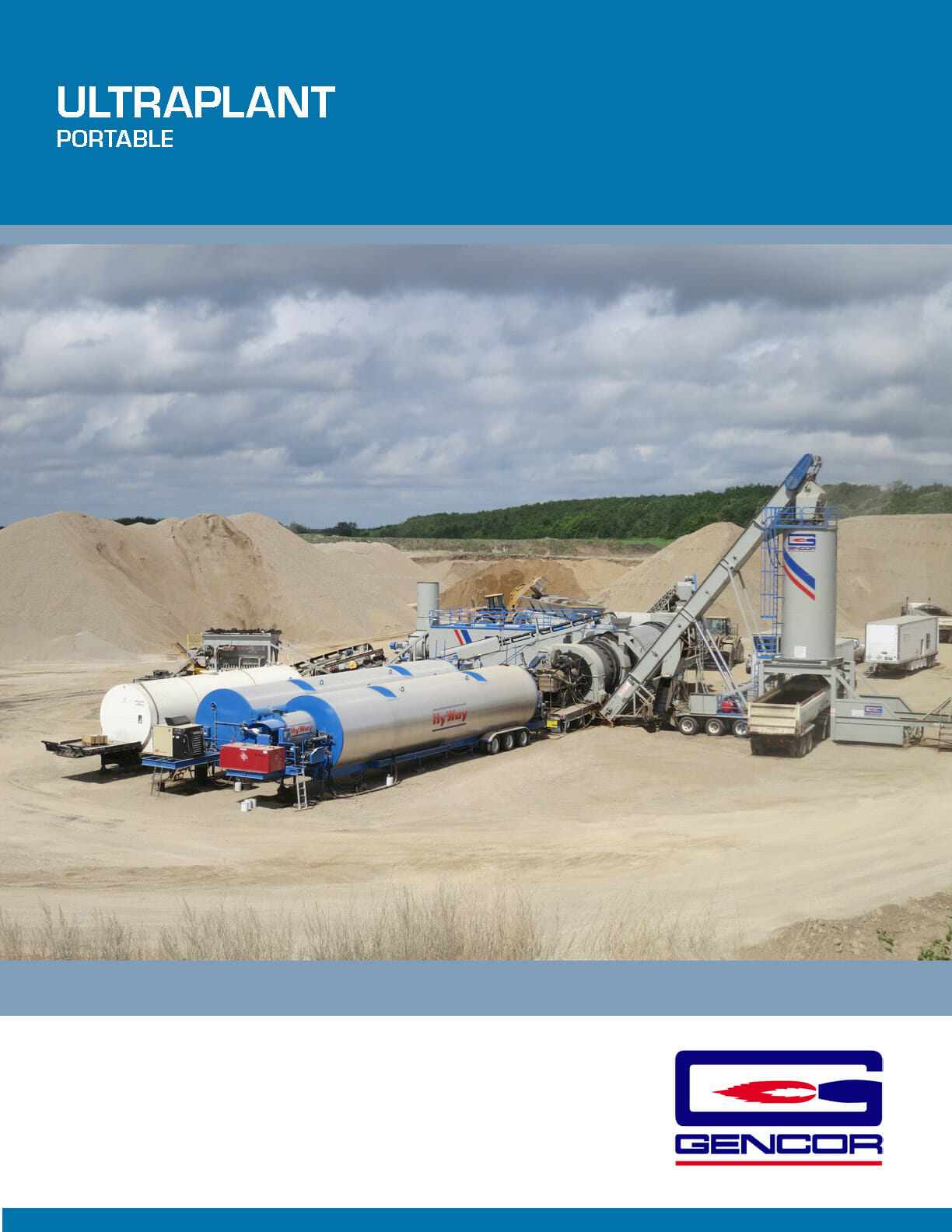

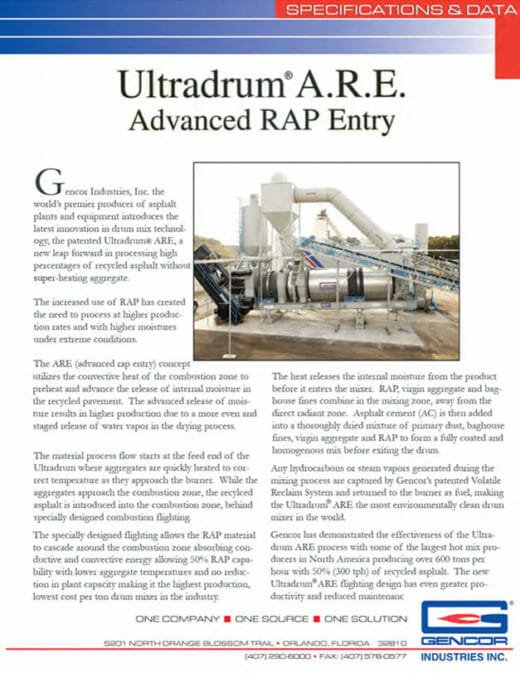

The heart of the Ultraplant® is built around the unique, patented counterflow Ultradrum® technology. The innovative Ultradrum® has been proven in hundreds of applications around the globe to cleanly and efficiently produce high-quality hot mix, without degradation. Designed with all the heavy-duty features you’ve come to expect from Gencor, the Ultraplant® is without question the heaviest built and most rugged drum mix plant in the industry.

Standard Features:

- Patented 5-way adjustable Converta® flight

- Patented combustion T-flights reduce energy costs

- Sweeping material inlet flights for even drum loading

- Self-cleaning RAP inlet allows up to 50% RAP

- Larger drum diameter reduces air velocity & dust carry-out

- Friction driven trunnion rolls for lower noise, maintenance, and energy

- Positive volatile reclaim system captures and destroys hydrocarbons

Advantages:

- Patented blue smoke system

- Adjustable mixing flights

- Total Air Low Nox Combustion

The isolated mixing section is located behind the burner so there is no chance of liquid asphalt coming in contact with the burner flame. This means there is no oxidation of the asphalt, no degradation of the mix, and no asphalt vapors entering the exhaust gas stream. Vapors generated in the mixing section are pulled through the burner by a patented volatile reclaim system and consumed as fuel. There are no odors or blue smoke emissions to pollute the environment.

The Genco Ultra II burner is extended well inside the dryer for maximum efficiency and contact with the wet aggregates. There are no refractory chambers or high maintenance combustion ports. The Ultra II is the only burner to use compressed air to atomize each droplet of fuel for optimum fuel efficiency.